Sprinkler System Tune-Up

Once a year you should give your sprinkler system a "tune-up". Most people do this at the start of the irrigation season. First we'll look at some necessary definitions, then I'll tell you how to tune-up your sprinkler system.

Spray-type sprinklers (often simply called "spray heads" or "sprays") are the sprinklers that create a fixed fan-shaped spray pattern, somewhat like a shower nozzle spray.

Spray-Type Sprinkler Heads

Rotor-type sprinklers (called "rotors") are the sprinklers that have one or more streams of water that rotate over the landscape. Some have a single stream that goes back and forth, or just goes in a complete circle. Another type are called "stream rotors", these have several fingers of water that rotate around the sprinkler in the same direction and look like spider legs. The bottom line is that if the sprinkler has a stream of water that rotates, it is a rotor-type sprinkler.

Rotor-Type Sprinkler Heads with Single Stream.

A valve circuit or valve zone is a group of sprinklers that are all turned on and off by the same valve. Sometimes the term hydrozone is also used, although this is not a totally correct useage. Most sprinkler systems have several valve circuits, each controlled by a different valve. The valves might be manually operated, or they may be automatic valves that are turned on and off by a controller (sometimes called a timer or irrigation clock). On the controller the valve circuits may be called valve stations. Unfortunately the lack of uniform names makes it confusing.

Sprinkler System Tune-up Step 1:

Check for problems. Turn on each valve, one at a time, and carefully inspect your irrigation system. Look for wet spots that indicate there might be a leaking irrigation pipe. Repair any leaks.

Replace controller battery. Most irrigation controllers have a back-up battery that maintains the time and program during power failures. Typically it is a standard rectangular shaped 9-volt alkaline battery. Check the battery in the irrigation controller. Replace it if it is not fully charged, or if it is more than a couple of years old. The battery is often located behind the front panel of the controller. Depending on the model, you may need to remove some screws or unhook a latch to open the panel and get to it. Check your owner's manual. Here's a bit of trivia to stick in the back of your brain until needed: if the controller no longer shows the correct time after a power failure the problem is likely that a battery needs to be replaced in it.

Straighten any sprinkler heads that are leaning to the side. In most situations sprinkler heads need to be installed so that they are perpendicular to the ground to work correctly. On a level area this means they would be positioned straight up and down so that they do not lean towards any side. If they lean to one side they may create dry spots and also waste lots of water. On slopes the general standard is to position the sprinkler heads perpendicular (at a right angle) to the slope. However you need to use comon sense here. On steep slopes you may want to lean the heads slightly toward the top of the slope. With the sprinkler turned on, look at the spray pattern. If the uphill side is spraying almost straight up into the air, you need to lean the sprinkler a bit toward the top of the slope, otherwise the water is just spraying straight up and all falling in the same place, or blowing away. When a full circle sprinkler head is located at the bottom of a slope it is a common problem for it to spray directly into the ground on the downhill side. You may need to lean it a little toward the top of the slope to correct the problem. I typically lean the sprinklers slightly toward the top of the slope on my systems, but most experts do not agree with me on this, so I may well be wrong.

Replace any broken or malfunctioning sprinklers. Straighten any sprinklers that are leaning. Be sure to replace broken sprinklers with the same brand and model as the other sprinklers on the same valve circuit. If some of the sprinklers are already mis-matched you need to replace them so that all the sprinklers controlled by any single valve are matched. Mixing different brands and types of sprinklers together on the same valve circuit is a common mistake made by do-it-yourselfers. Most brands and models of sprinklers are not compatible with any other brands or models. While there are exceptions, most manufacturers use different flow rates in their sprinkler heads than their competitors. (It makes sense doesn't it? They want you to use their sprinklers for replacements, not the other guys! You can't use Chevy parts in a Ford either.) Mixing different brands and models of sprinklers together on the same valve circuit can result in huge amounts of water wasted. Mixing them is like putting a heavy kid and a light kid on a teeter-totter. It doesn't work! If the original brand used is not available, you have two choices:

- See if you can find a model with the same flows for the same exact pressure and radius of throw. This takes a lot of time if you do it yourself. You could save some time and effort by asking for help at a professional irrigation store (your local big-box store is generally not a good place to ask for help on this issue), or see if I have reviewed the sprinkler model you are using. In my reviews I often mention other compatible models. Important note; just because a part will screw on, that doesn't mean it is a match. It just means it has similar size threads, which are standardized. You can fit a Hunter brand spray nozzle on a Rainbird brand body, but the Hunter nozzle is not a performance match with the Rainbird nozzles.

- Change all the sprinklers to another model. Often option (2) is not a bad idea, if the sprinklers are no longer available they are likely pretty old, or they weren't great to begin with (that's why they aren't sold anymore?)

It should be obvious that if you can't mix different sprinkler models on the same valve circuit, then you should also never mix spray-type heads and rotor-type sprinklers on the same valve zone. Mixing rotors and sprays together on the same valve is even worse than mixing brands and models! Spray-type heads put out twice as much water as rotors given the same size area! If you mix them together the grass near the spray-type sprinklers will be drowning, while the grass around the rotors has just barely enough water to keep it alive! (I'm getting over-excited and using too many exclamation marks.) Check it out yourself, you will see the area around the spray heads is really wet compared to the area around the rotors.

Clarification- we are discussing why you should not mix different brands or models of sprinklers together on the same valve circuit. Check the definition of valve circuit again at the top of the page if you are not clear about this. You MAY use different brands and types if they are on different valve circuits. So you could have one valve circuit with Rainbird spray heads on it and another valve circuit with Hunter rotors on it. That would be OK. Also, the don't mix them rule is only for sprinklers. You can use a different brand of valve for each valve circuit without problems most of the time. In most cases the automatic valves don't have to be the same brand as the controller either.

Sprinkler System Tune-up Step 2:

Clean spray-type sprinklers. If you have spray-type sprinklers start by removing the nozzle from each head and cleaning the screen. The screen will be under the nozzle, you may need a bent paper-clip to use as a hook to pull it out. An old toothbrush works good for cleaning the filter. Reinstall the filter and put the nozzle back on. Next, turn on the sprinklers and look for partially blocked nozzles. The fan-shaped spray of water out of each nozzle should be even and uniform across the entire width. Uneven gaps in the fan indicate a grain of sand is stuck in the nozzle, remove the nozzle and carefully clean it. To clean plastic nozzles use a plastic or wood tool (like a toothpick) rather than a metal knife blade. Try not to scratch plastic nozzles when cleaning them, even a small scratch can ruin the spray pattern. If you have any doubts just replace the nozzle with a new one. Most pros don't bother trying to clean nozzles, they scratch so easy it's just faster and cheaper to replace them rather than waste the time trying to clean them.

Sprinkler System Tune-up step 3:

Adjust spray-type sprinklers. On top of each spray-type nozzle is a small radius adjustment screw. Turn the adjustment screw to adjust each of your spray-type sprinklers so that they don't spray onto sidewalks or walls. If spray-type heads are creating a lot of mist try partially closing the adjustment screws on them (turn the screw clockwise to reduce the misting.) You will likely discover that you can turn the screw considerably without it actually reducing the spray distance. Partially closing the adjustment screw will reduce the water pressure inside the nozzle, which will cut down on how much mist is created. After adjusting, make sure that the spray from the nozzle still goes all the way to the next sprinkler. When sprinklers are properly spaced and adjusted the water from each sprinkler should spray all the way to the next sprinkler in each direction. This is how sprinklers are designed by the manufacturers to be spaced. I know it seems like a waste but there is actually a reason it is necessary that is related to the physics of water application, but you don't really want a science lesson now do you? Take my word for it, there should be 100% overlap of the watered areas. This is true for both spray-type sprinklers and rotor-type sprinklers. In the industry we call this "head-to-head spacing". If you don't want to take my word for it, call a sprinkler manufacturer's help line and ask them.

Adjustment Screw on a Spray-Type Sprinkler

Sprinkler System Tune-up Step 4:

Clean rotor-type sprinklers. Most pop-up gear-driven rotors have a filter in them that can be cleaned. Gear driven rotors are identified by the very quiet operation and the water stream that moves smoothly as it rotates. The water stream on a gear-driven rotor always rotates at the same speed. However getting to the filter is difficult, you must unscrew and remove the cap on the top of the rotor. When you remove the cap the nozzle and drive assembly will be attached to it and come out with it. Look for the screen on the bottom of the drive assembly you just pulled out. The problem is that when putting the drive assembly back into the body, you often will get more dirt into the body than you just removed from the screen! Thus the final condition is worse than when you started. So I don't recommend cleaning the screen on rotors unless you are having problems with them. If you do clean them be very careful that dirt does not get knocked into the body when you put the cap back on. A weak water stream from the rotors, a reduction in the distance the water throws, or dry spots in the lawn that never were present before would all indicate the screen may be clogged and you should clean it. Be aware that all of those problems can result from other causes also, so cleaning the filter screen is not a guarantee cure!

Impact drive rotors: Impact drive rotors are the ones that have an arm that swings back and forth, hitting the water stream. The impact of the arm striking the water stream causes the nozzle to rotate slightly, thus the name "impact drive" or simply "impacts". Impacts are easily identified by jerking movement of the water stream, and the sound they make as the arm strikes the water going forward; chuk, chuk, chuk, chuk, and then reversing direction; tikka, tikka, tikka. The water stream moves faster when it reverses direction. Pop-up impact sprinklers often have large diameter cases due to the size of the impact arm. The pop-up impact drive rotors also often have a screen, however it requires a special tool to get to it. You will need to go to a irrigation specialty store to get the tool. Generally this is not worth the effort. The simple impact sprinklers mounted above ground on a pipe do not generally have a screen.

Impact Driven Rotor (mounted on pipe above ground)

Sprinkler System Tune-up Step 5:

Adjust the rotor-type sprinklers. For rotors the most common adjustment error is to try to create even coverage by breaking up the water stream using the radius adjustment screw. On a typical rotor the radius adjustment screw is located on top of the sprinkler, just in front of the nozzle. When turned the screw drops down into the water stream causing the stream to deform. This deflects the water stream and reduces the distance it shoots from the sprinkler.

Most newer rotors give the best, most uniform, coverage when the screw is not touching the water stream at all. This is not true of older rotors (at least 20 years old) and really cheap rotors that don't have engineered nozzles. Often these inexpensive rotors require the radius adjustment screw be used to break up the stream. Most turbine/gear-driven rotors have engineered nozzles and don't need any adjustment to break up the water stream. Don't worry if it looks to you like most of the water is falling at the edge of the pattern, this is normal. Most people can't see the small droplets of water that fall in the area closer to the sprinkler head, so it looks to them like the sprinkler is out of adjustment.

Turn the adjustment screw clockwise until it is touching the water stream (you will notice the stream change shape when the screw contacts it.) Now turn the screw counter-clockwise just enough that it is not touching the stream. This is the proper default position, unless the sprinkler is spraying too far you should leave it in this default position. Warning: the adjustment screw also holds the nozzle in place on most gear-drive rotors. Stop turning the screw when it no longer touches the water stream. If you turn the screw too far, or remove it, the nozzle will fly out and you may never find it! OK, now if the stream of water is going too far, you can turn the screw clockwise until the distance is reduced to keep it within the irrigated area. Use the radius adjustment only if you need to actually reduce the radius so the water doesn't spray on something like a sidewalk or the house.

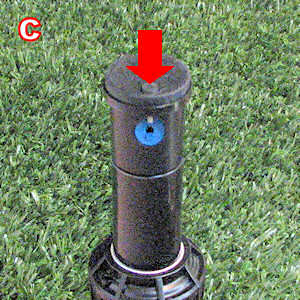

Typical Gear-Drive Rotor Radius Adjustment Screw Locations:

A - Silver screw near edge, above nozzle.

B - Silver screw near edge, above nozzle.

C - Screw under a rubber flap, near edge, above nozzle.

D - Stream rotor nozzle, screw is in center of sprinkler.

On rubber top rotors the adjustment screws are under rubber flaps. Push the screwdriver through the slits on the rubber cap to reach the screw under the flap.

Check the yard in a week or so. Dry areas located midway between the rotor heads usually indicate the adjustment screw is too far into the water stream, or the sprinklers are spaced too far apart (check the manufacturer's recommended spacing.) If a yellow "donut" shaped dry area develops around the sprinkler this indicates that you either have one of those cheap rotors without engineered nozzles, or the rotor sprinkler does not have enough water pressure. Typically lack of water pressure is because the pipe that leads to the rotor is too small, or there are too many sprinklers on the valve circuit. This is a design problem, but it is a bit late for easily correcting it now. If donuts appear, try adjusting the radius screw so the end of the screw just slightly touches the water stream. That should cause more water to fall in the dry donut area. You may need to experiment with different settings until you get the best possible results.

If you don't want to wait for dry spots to appear in your lawn, there is a short-cut way to check the adjustment and coverage uniformity of your sprinklers. Place identical-size cups, more or less evenly spaced, throughout the area watered. The cups should be between 5 and 10 feet (1,5m to 3m) from each other. Keep the cups at least 3 feet (1m) from any sprinkler heads, if they are closer than that to a sprinkler you will get inaccurate results, also keep the cups at least 12" from the edge of sidewalks, curbs, patios, or other paved surfaces. Disposable plastic or foam cups work good but tend to get knocked over by the water stream. Here's a trick- place a stake made from a piece of stiff wire (ie; a wire coat-hanger) next to each cup and use a couple of rubber bands or masking tape to strap the cup to the stake. Run the sprinklers for a few minutes so that the cups are at least 1/4 full, if you have rotors the slowest moving one should make at least 5 passes over the cups. Now compare how much water is in the cups. When the sprinklers are properly adjusted each cup should have about the same amount of water in it. Be warned, it is not always possible to get it perfect if there is an underlying design problem with the sprinkler system. If you want to try to fix the design problem, try creating a new design following the method in the Sprinkler Design Tutorial. Then compare the optimal design you just created with what is actually installed. You may see some possible ideas for improving the system.